PRODUCTS | MATERIALS

Fillers and Putties

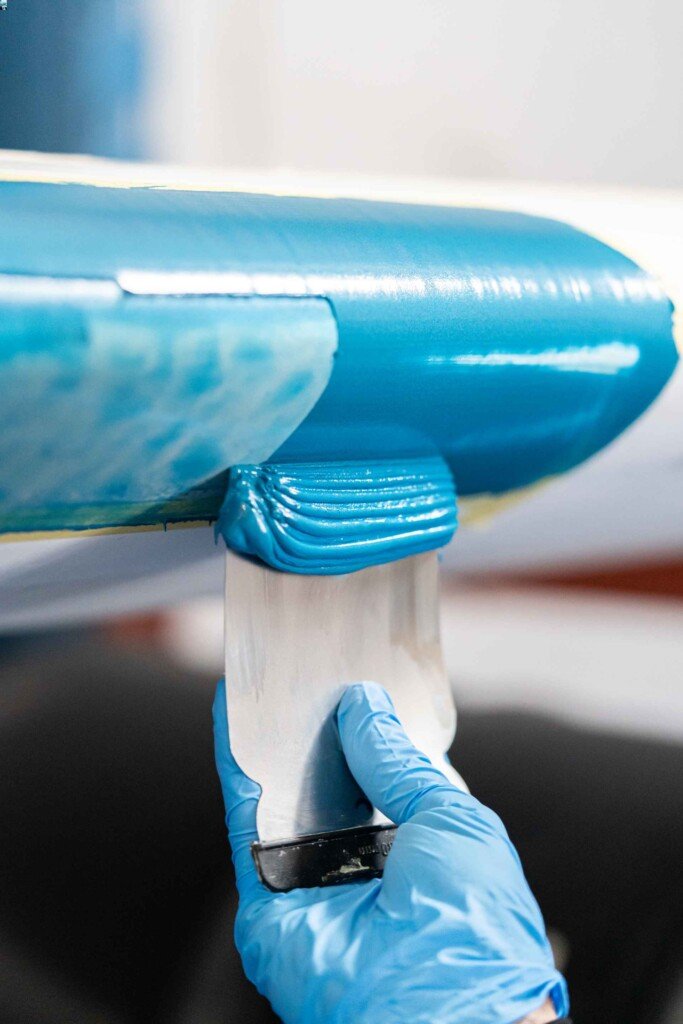

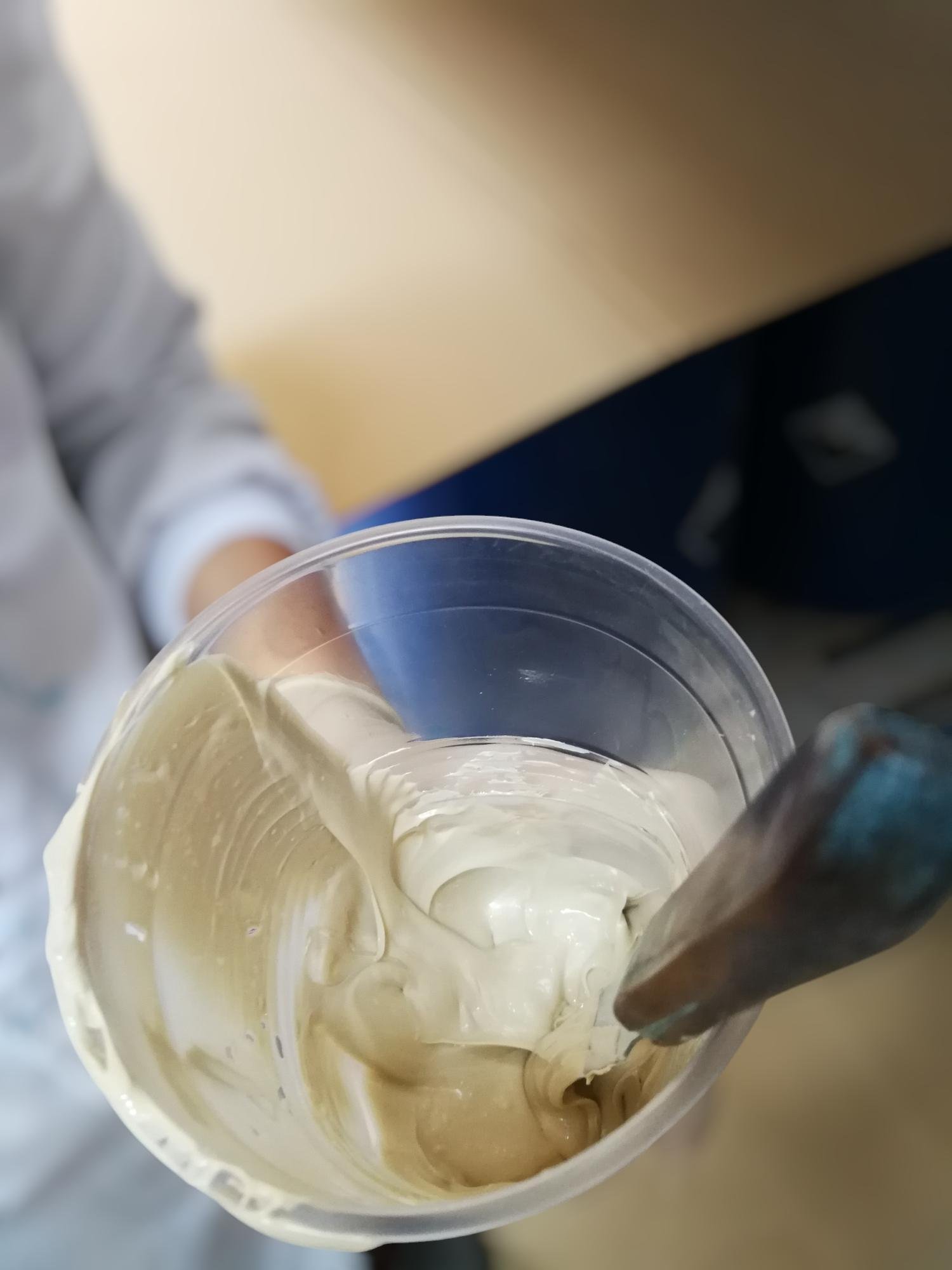

The range of Fillers and Putties AROFILL® are 2-component Epoxy or PU fillers with excellent adhesion properties, extremely easy to apply, providing a smooth surface to apply on.

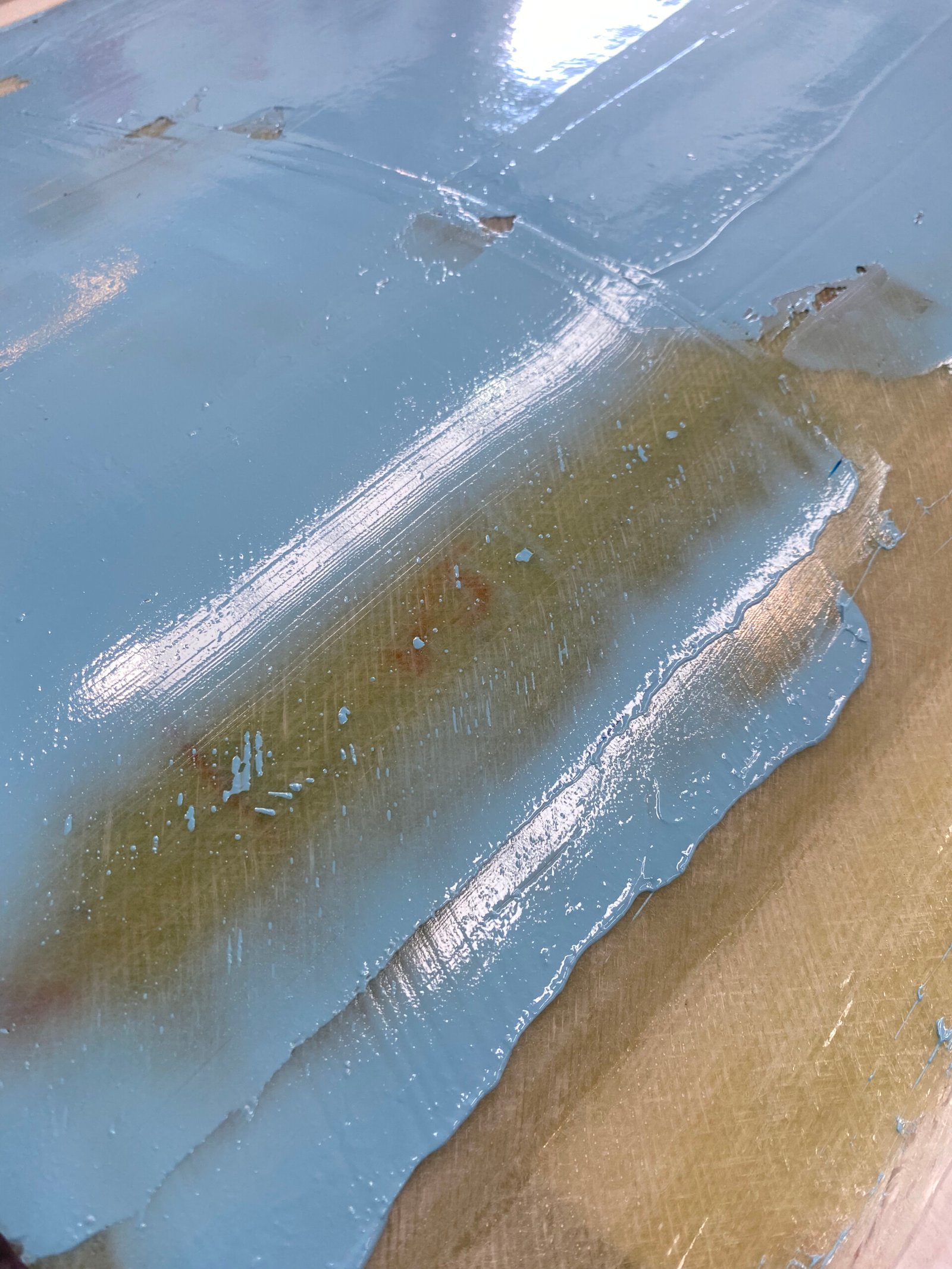

This range of products are specifically designed to achieve an optimum aerodynamic surface of wind turbine rotors blades

They are used to repair large defects and can be used as pore filler to cover small defects like pinholes appearing at different stages of the manufacturing process of a WT

AROFILL® has extended working time which allows an easy manipulation and fast sanding times with a good-finish surface, and an outstanding mechanical behavior even at low temperatures.

Fillers & Putties Range

AROFILLTM 903

POLYUTHERANE BASED

Performance & Features

| Mix Ratio (by weight) | 100:25 |

| Gel time | 4-5 min |

| Sag resistance | >4 mm |

| Drying | |

| Easy to sand |

AROFILLTM 890

Epoxy Based

Two-components, Epoxy based, easy to sand, fast curing, smoth surface.

Performance & Features

| Mix Ratio (by weight) | 100:56 |

| Gel time | >35 |

| Sag resistance | >4 |

| Fatigue response | |

| Drying | |

| Easy to sand |

AROFILLTM 907

Polyurethane Based

Two-components, Polyurethane based, easy to sand and very fast curing time.

Two versions (SLOW and FAST) are available, designed as a pore filler and can be pigmented in different colors (RAL).

Available version for service (repair and maintenance).

Performance & Features

| Mix Ratio (by weight) | 100:33 |

| Gel time | >5 m |

| Sag Resistance | >4 |

| Drying | |

| Easy to sand |

AROFILLTM 914

POLYURETHANE BASED

Performance & Features

| Mix Ratio (by weight) | 100:10 |

| Gel time | 10-20 min |

| Drying |