Two-components, excellent compromise between curing behavior and open time

Products

Polymer Solutions for Wind Turbine Rotor Blades

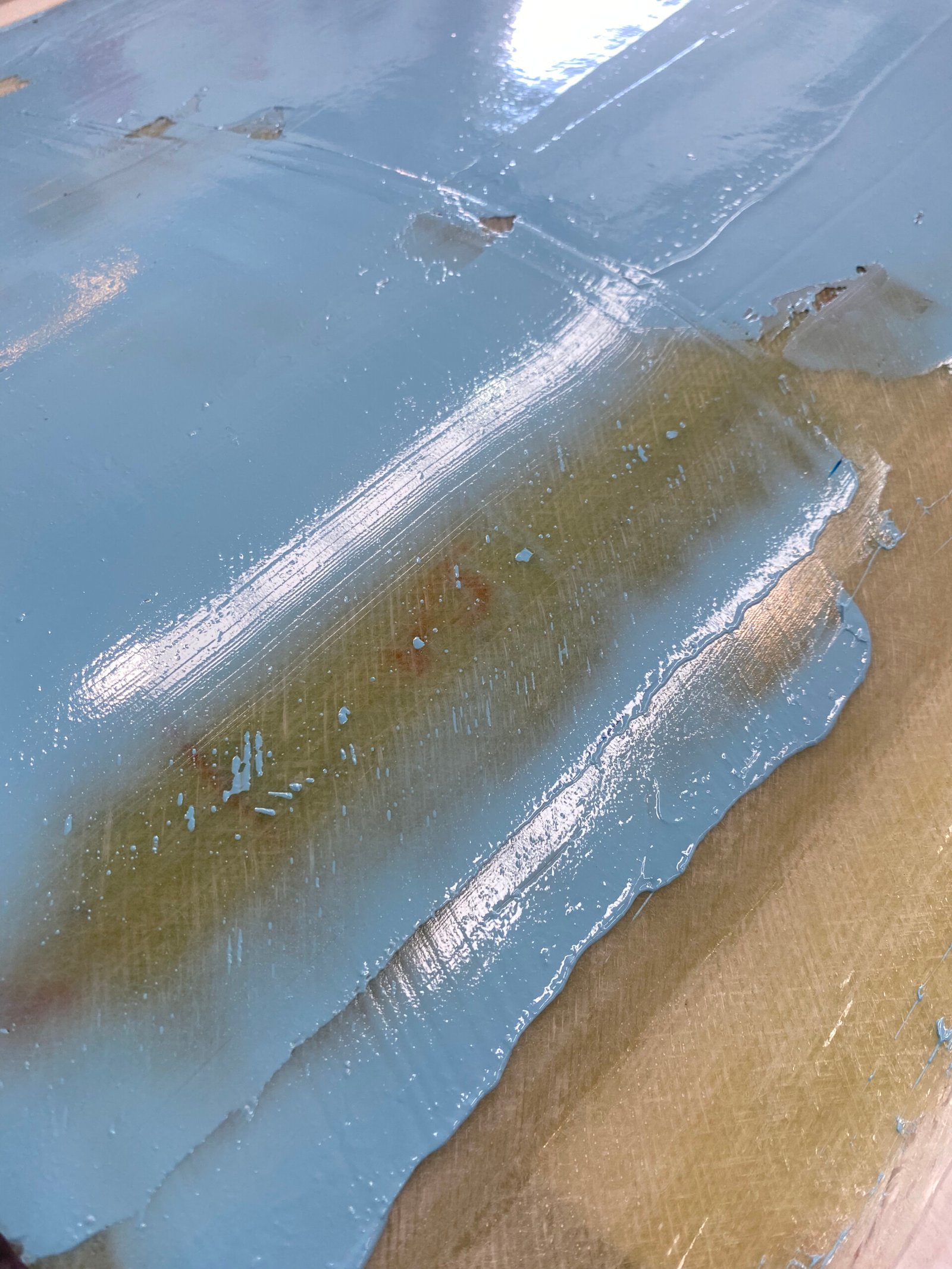

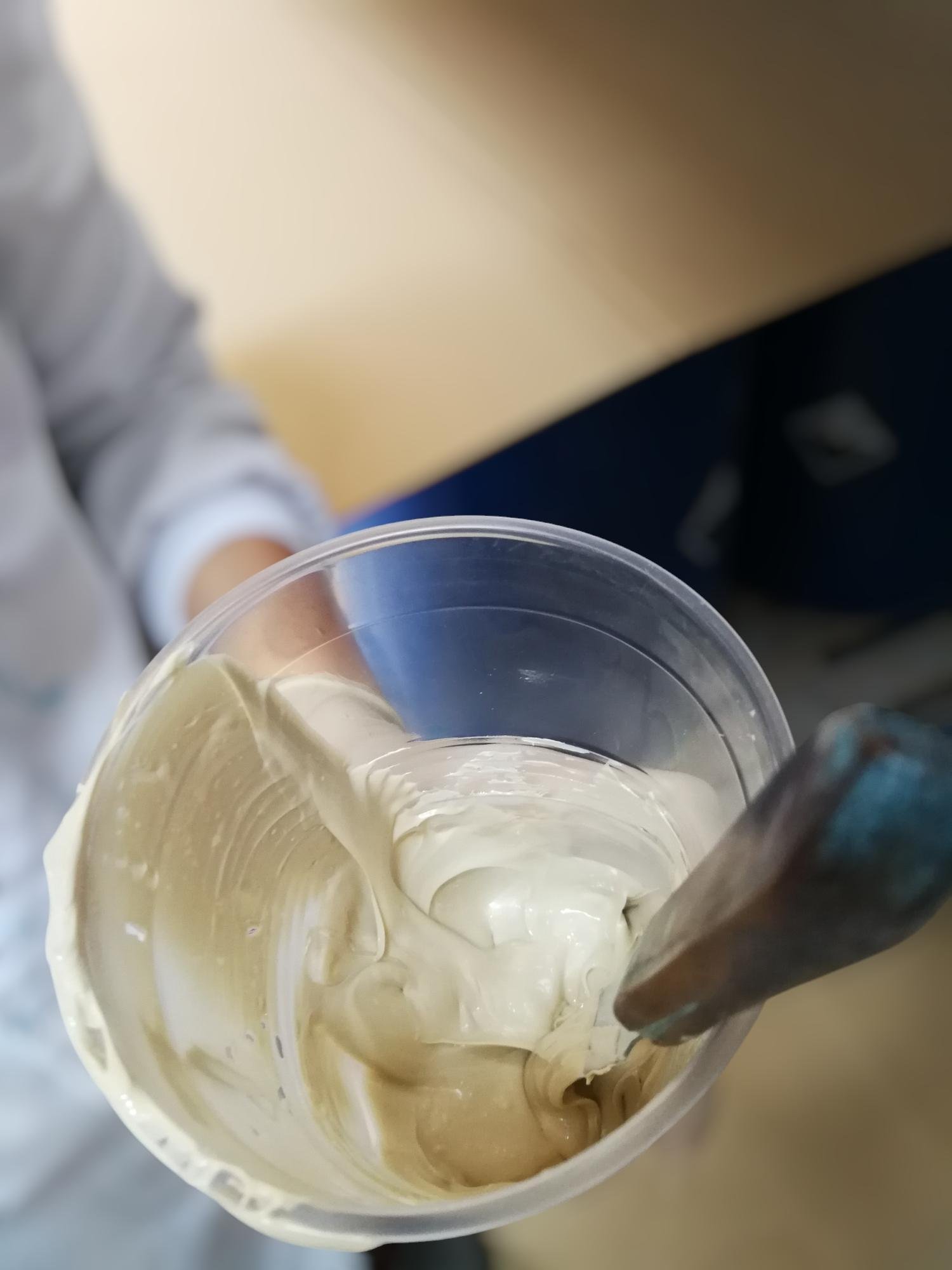

We strive to offer our customers a complete portfolio of products, so all blade finish layers are provided from one single source. Our product mix includes gel coats, filler & putties, topcoats & primers and LEP, with versions for both manufacture and repair of blades. With regard structural products, our portfolio includes bonding paste solutions both in glass filled and toughened technologies to better support all our customer needs.

Our deep material knowhow in both Epoxy and PU chemistry technologies, together with our blade manufacturing expertise in the field, makes us the best partner for your future product developments.Our goal is to get you outstanding materials, in line with the most demanding physical properties performance and in extreme weather conditions. We target to reduce your production takt time while balancing material cost and the overall blade weight.

Filter by:

Manufacturing Process

Aplication

Technology

Epoxy Glass Filled

Two-components, excellent compromise between curing behavior and open time

| Mix Ratio (by weight) | 100:45 |

| Ultimate Tg | >90 |

| Sag resistance | >20 mm |

| Open time | |

| Processability |

Epoxy Thoughened

Two-components, High fracture toughness response, low density

| Mix Ratio (by weight) | 100:33 |

| Ultimate Tg | >75 |

| Sag resistance | >20 mm |

| Open time | |

| Processability |

Repairs

| Mix Ratio (by weight) | 100:46 |

| Ultimate Tg | >60 |

| Sag restistance | 0 mm |

| Open time | |

| Processability |

POLYUTHERANE BASED

| Mix Ratio (by weight) | 100:25 |

| Gel time | 4-5 min |

| Sag resistance | >4 mm |

| Drying | |

| Easy to sand |

Epoxy Based

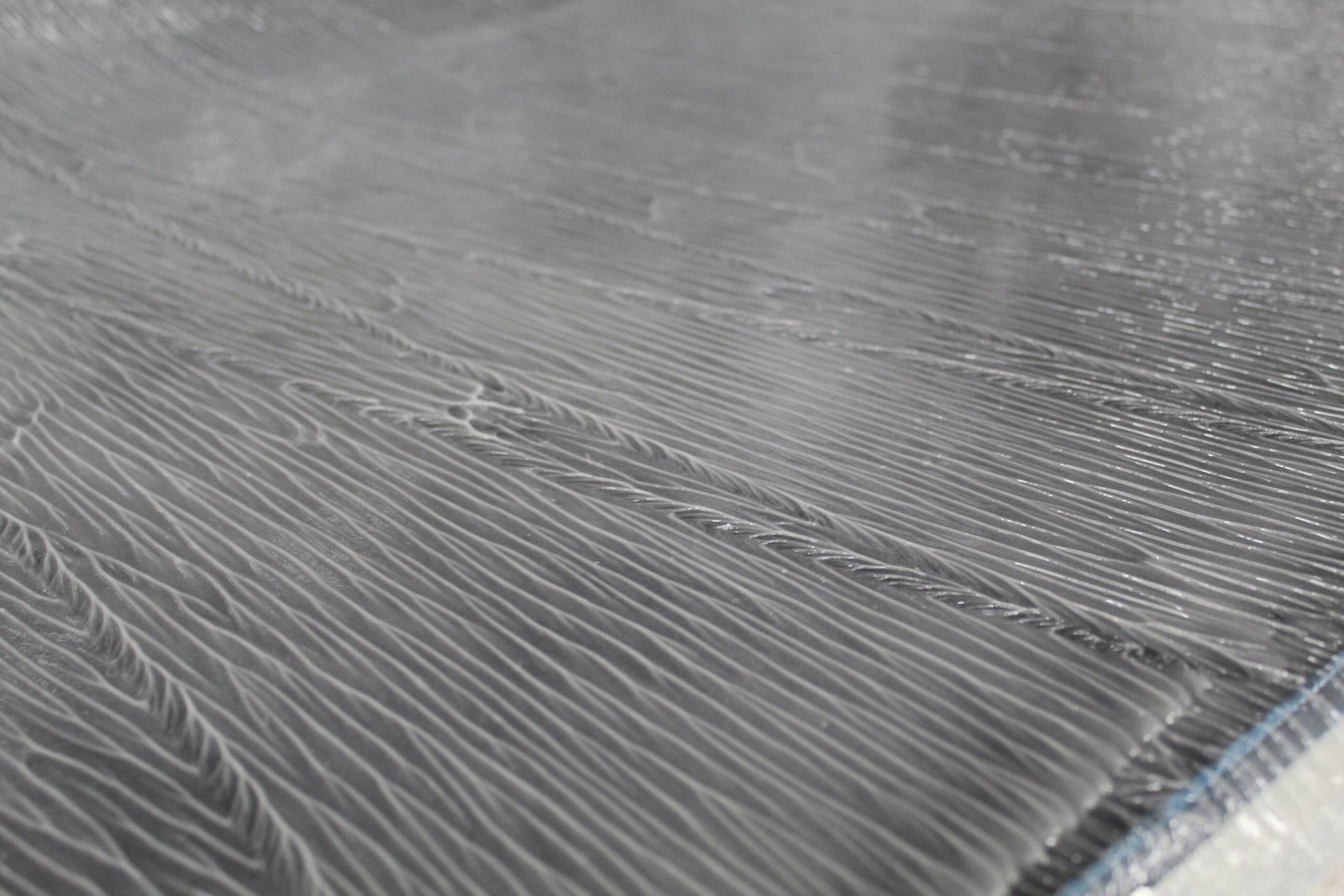

Two-components, Epoxy based, easy to sand, fast curing, smoth surface.

| Mix Ratio (by weight) | 100:56 |

| Gel time | >35 |

| Sag resistance | >4 |

| Fatigue response | |

| Drying | |

| Easy to sand |

Polyurethane Based

Two-components, Polyurethane based, easy to sand and very fast curing time.

Two versions (SLOW and FAST) are available, designed as a pore filler and can be pigmented in different colors (RAL).

Available version for service (repair and maintenance).

| Mix Ratio (by weight) | 100:33 |

| Gel time | >5 m |

| Sag Resistance | >4 |

| Drying | |

| Easy to sand |

POLYURETHANE BASED

| Mix Ratio (by weight) | 100:10 |

| Gel time | 10-20 min |

| Drying |

LOW UV RESISTANCE

Two-components, traslucent, easy sanding, fast curing, suitable for infusion prepreg/process

| Mix Ratio (by weight) | 100:20 |

| Ultimate Tg | >90 |

| Gel Time | >12 |

| Easy to sand | |

| Drying |

HIGH UV RESISTANCE

Two-components, high UV resistance, coloured, easy sanding, suitable for infusion/prepreg process

| Mix Ratio (by weight) | 100:19 |

| Ultimate Tg | >90 |

| Gel Time | >12 min |

| Easy to sand | |

| Drying |

HIGH UV RESISTANCE

Two-components, high UV resistance, traslucent, easy sanding, fast curing, suitable for prepreg/infusion process

| Mix Ratio (by weight) | 100:20 |

| Ultimate Tg | >90 |

| Gel Time | >12 |

| Easy to sand | |

| Drying |

Fast Curing

| Mix Ratio (by weight) | 100:11 |

| Gel time | 30 min |

| Sag resistance | >300 |

| VOC'S content | |

| Color retention |

Fast Curing

Three-components, fast curing, solvent-based paint, very good surface finish.

Available version (2K) for service (repair and maintenance).

| Mix Ratio (by weight) | 100:20 |

| Gel time | >4 |

| Sag Resistance | >200 |

| VOC'S content | |

| Color Retention |

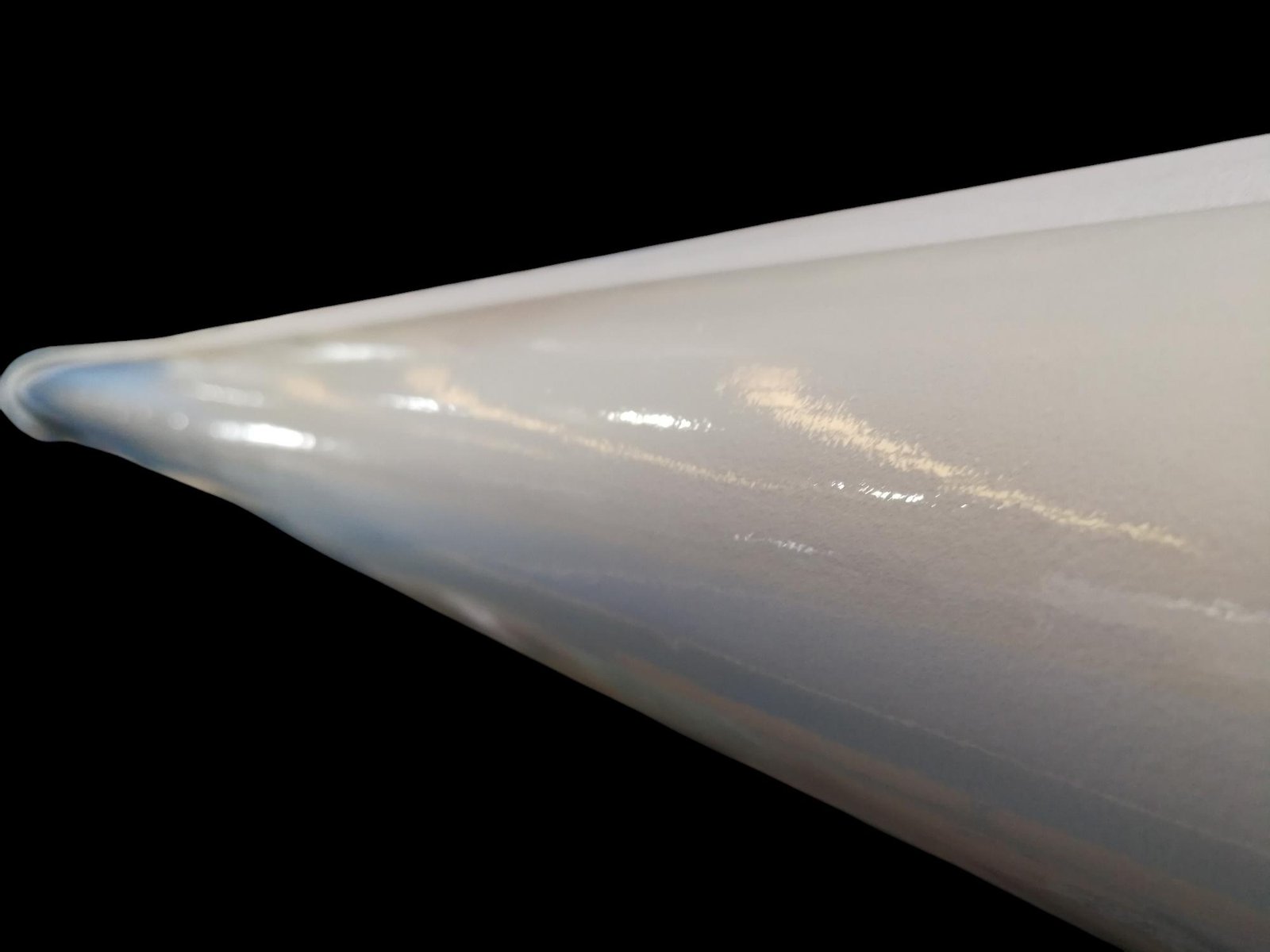

Polyurethane Based

| Mix Ratio (by weight) | 100:100 |

| Pull-Off adhesion | >5 Mpa |

| Rain erosion resistance | 40 hrs until breakthrough at 160 m/s tip speed |

| Gel time | >5 min |

| Easy to use |

Polyurethane Based

| Mix Ratio (by weight) | 100:100 |

| Pull-Off adhesion | >5 Mpa |

| Rain erosion resistance | 15 hrs until breakthrough at 130 m/s tip speed |

| Gel time | >7 min |

| Easy to use |

Polyurethane Based

Two-components, Poliurethane based, fast curing time, proven efficiency, high UV, rain and abrasion resistance

| Mix Ratio (by weight) | 100:50 |

| Pull-Off adhesion | >5 Mpa |

| Rain Erosion Resistance at 105 m/s tip speed | >16hrs(Small spots of erosion) |

| Gel time | >14 min |

| Easy to use |